From a long black to a flat white and everything in between, whatever your coffee preference may be, the majority of us will enjoy a coffee or two every day. Suntory Coffee has been roasting, blending and grinding coffee since 1952. The creators of the first wave of espresso in New Zealand, and the pioneers of the 1990’s cafe culture, Suntory Coffee is home to some of New Zealand’s most loved, most consumed and most well-known coffee brands such as Robert Harris, Orb Espresso & Bruno Rossi Coffee.

At the head office in Auckland, Suntory Coffee recently completed the build of New Zealand’s newest and largest fresh coffee roasting operation. This purpose-built coffee roasting and warehousing operation is where many of the Suntory Coffee brands are processed ready for despatch to cafes, restaurants and supermarkets across New Zealand.

Sourcing high quality

& reliable equipment

When Cameron Russell, Project Engineer at Suntory Coffee began planning the new purpose-built facility, the selection of equipment – including the compressed air system – was an important detail in developing a plant that would be durable and reliable. From coffee bean roasting, to powering control valves that select the required coffee bean silo, right through to grinding, blending, processing and packaging – compressed air is an essential utility that would be required for many purposes within the new facility.

After considering a number of options, Suntory Coffee opted for an all-in-one Kaeser Aircenter SK25 compressed air station along with filtration and a DHS 4.0 air-mains charging system to meet these requirements.

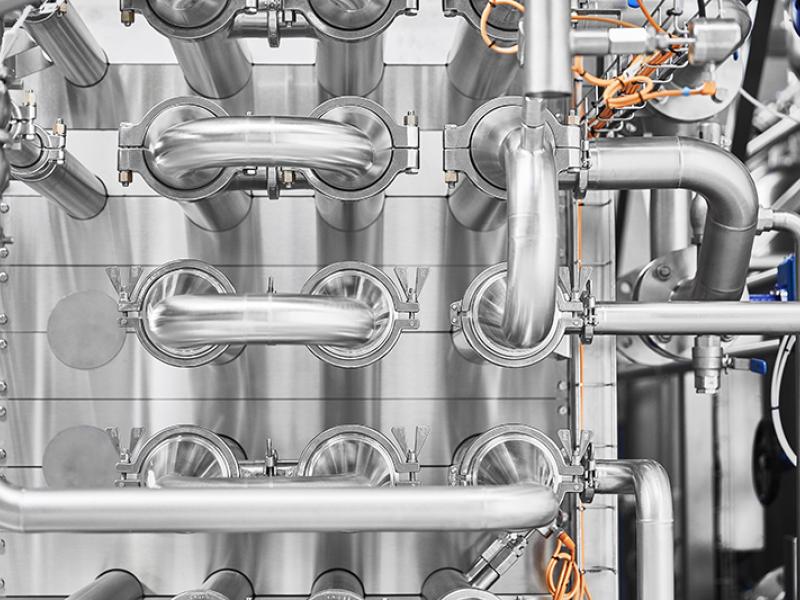

Remaining proudly manufactured in Germany, the user-friendly Aircenter from Kaeser Compressors is a complete turnkey system which incorporates a Kaeser rotary screw compressor – complete with the highly efficient Sigma Profile screw compressor block – an energy efficient refrigeration dryer and an air receiver all in one space-saving compact package.

At the heart of the Aircenter’s rotary screw compressor lies a premium quality screw compressor block featuring the Kaeser Sigma profile rotors. Superior efficiency is assured with these flow-optimised rotors that are able to achieve power savings of up to 15 percent compared with conventional screw compressor block rotor profiles. In addition, maximum energy savings and outstanding system performance are assured thanks to the inclusion of a premium efficiency IE3 motor which complies with and exceeds prevailing New Zealand EECA regulations for three-phase electric motors.

The Aircenter is user and maintenance-friendly. With the internal Sigma Control 2 controller, compressor performance can be easily controlled and monitored for optimum efficiency. In addition, all maintenance and service points are easy to access. This significantly reduces the downtime associated with service and maintenance tasks and helps to increase compressed air availability and minimise operating costs.

Food grade standard compressed air

As the coffee can come into contact with the compressed air at certain stages of production, it was essential that the compressed air system produced food grade standard compressed air. To meet the air purity level required for food manufacture, the Aircenter at Suntory Coffee therefore operates with a food grade lubricant and filtration. In addition, a Kaeser DHS 4.0 air-main charging system was installed.

The DHS 4.0 series electronic air-main charging system not only provides protection for the compressed air treatment components, but it also helps ensure reliable compressed air quality – even following a complete shutdown of the compressed air supply system, for example at weekends.

Such a surge can lead to filter element damage and to a raised pressure dew point in the refrigeration dryer. As a result, contaminants such as oil, particulate matter and humidity are introduced into the pipe distribution network and the process air. The DHS 4.0 eliminates these risks by guaranteeing necessary minimum pressure, which consequently ensures smooth network start-up and safe operation of the compressed air station.

During system operation, it also helps to ensure consistently high compressed air quality. If a fault were to occur with a dryer or a filter, for example, the DHS 4.0 is able to shut down and isolate the affected treatment line. This not only assures consistent air quality, but also safeguards the pipe distribution network and the air consumers in the production facility. By minimising the burden on compressed air treatment components, air receivers and pipe networks and preventing surge loads caused by large changes in pressure from occurring, it consequently enables long service life, which in turn leads to considerably reduced costs.

Conclusion

The new facility has now been in operation for over 18 months. “From the coffee roasting right through to the processing facility – the selection of equipment for this project was really important in developing a plant with a high degree of reliability and performance,” said Russell. “Our selection of equipment has worked out to be a very good decision. And, when it comes to the Kaeser compressed air equipment – it is absolutely meeting our requirements backed up with very good customer service.”

The all-in-one Aircenter compressed air systems from Kaeser Compressors are available with drive powers of 2.2 to 15 kW, and produce flow rates from 0.26 to 2.55 m3/min, designed for pressures up to 15 bar.

Details, Ph: 0800 447 820; nz.kaeser.com.