STEM (Science, Technology, Engineering and Mathematics) continues to evolve and educational institutions are working hard to keep pace. As a result, deploying collaborative automation in the education sector has become increasingly important as learners continue to navigate the new and exciting world of Industry 5.0.

Today, both tertiary and secondary educational facilities are making robotic technologies accessible to students, in an effort to empower and educate through industrial training. With it is “the need to collaborate with large manufacturers who can make the technology easily available and accessible,” this according to Masayuki (Masa) Mase, Country Manager for Universal Robots Oceania.

“On local shores, we are committed to reducing the barriers to entry, by working closely with educational institutions. Whether it’s an opportunity to deploy a collaborative robot (cobot), provide training or general information, we are passionate about empowering the next generation of industry leaders.”

Looking to the future of work, Masa confidently acknowledges the fact that most STEM learners will encounter robots in their careers. “Bringing cobots into the classroom makes for more adequately prepared students who can enter the workforce feeling confident. Majority of employers will want the next generation of workers to be well-versed in robotics to ensure enhanced collaboration.”

Inquisitive minds create change

The combination of an inquisitive mind and technology cannot be underestimated. “In 2021, we ran a success story featuring Rowan Smith, a University of Technology Sydney (UTS) student who, through working with Universal Robots’ cobots, had the idea to start-up Tech Gym - a company aimed at patient upper limb rehabilitation using cobots.”

“This story is a good example of how early exposure to cobots can spark great ideas.”

Leading the charge is the educational sector is Korea. “The employment landscape changed drastically as a result of the COVID-19 pandemic and the Robot Campus of Korea Polytechnics University helped students keep pace by furthering their robotics knowledge and capabilities.”

The Robot Campus of Korea Polytechnics University was the first Korean university to specialise in robotics. The campus opened in 2021 with the aim of accelerating the learning and development of industry professionals as production technology converges with the field of robotics. The university chose Universal Robots for its classrooms due to three factors, namely: market share, durability and usability.

UR Academy’s online modules became the key curriculum in the Robot Campus’ classes on Universal Robots. “The modules teach the basics of operating collaborative robots and is now part of the core training for all students, quickly becoming an important course that sets their university apart from others.” Students are now learning with the UR Academy, acquiring basic safety, operation and connectivity technology skills with industrial devices deployed in the industry.

The UR Education Program

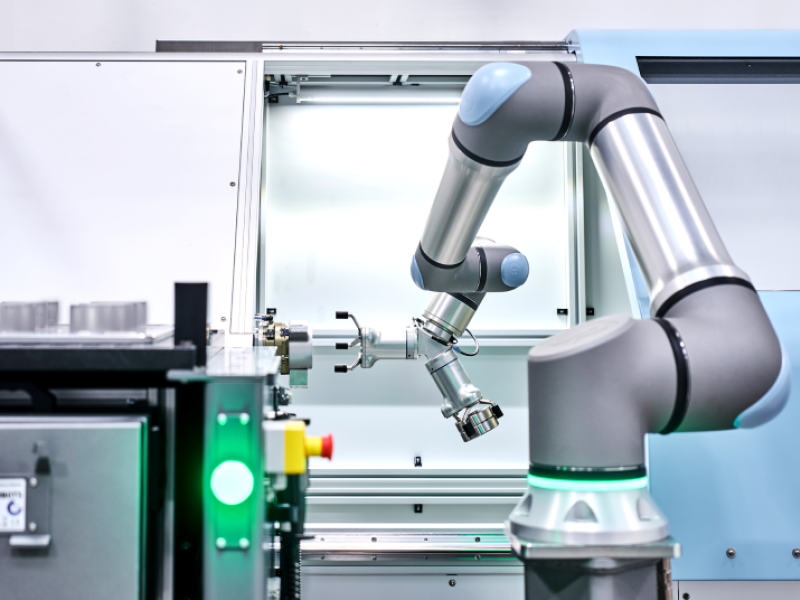

Universal Robots has introduced education kits to provide students with the direct, hands-on experiences of working with robotics hardware and software.

“The program includes access to our learning platform, a hardware kit (cobot), teacher training and teaching materials.”

The program offers an industry-recognised certification for teachers, who can then take students through the UR Academy Education program.

“This program is currently being rolled out globally and we believe that it could translate well on local shores. Through enhanced collaboration with our education partners, we look forward to creating a new generation of excited, engaged and empowered learners” he concludes.