While Industry 4.0 solutions have become increasingly popular, there are still many misconceptions surrounding this technology – particularly on the subject of robotics.

“Industry 4.0 is largely about digitisation, which entails bringing together the physical and virtual (computing) systems and unlocking the potential of robots and automation through better visualisation of data, increased flexibility, and decision making,” explains Wade Leslie, Country Sales Manager of KUKA Robotics Australia.

Wade is a member of Open IIoT, an initiative of some of Australia’s most prominent automation brands – including SMC, KUKA, Beckhoff Automation, Balluff, NORD Drivesystems and ZI-Argus that aims to demystify Industry 4.0 and related concepts.

“Another philosophy of Industry 4.0 is Batch Size One and ‘mass customisation’. It was conceived that software and to some extent, mobility, would facilitate the automated production of customised products,” he adds.

This understanding of Industry 4.0 as a concept focusing on high-level digitisation and mass customisation is at the core of Wade’s argument that robots, and ‘cobots’, are typically deployed as Industry 3.0 solutions – not Industry 4.0 as is commonly believed.

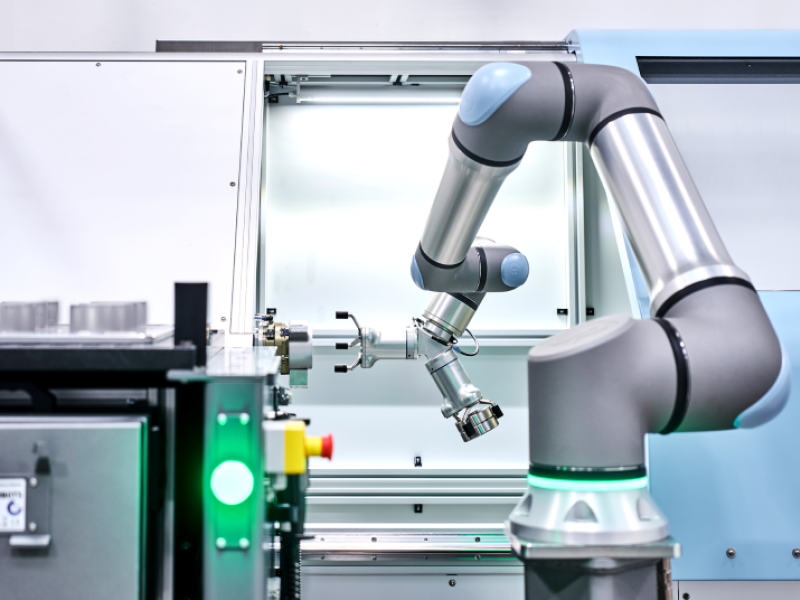

“There’s a common misconception that Industry 3.0 means outdated technology and an assumption that because cobots are relatively new, they must be part of Industry 4.0. However, robotics became mainstream during the third industrial revolution and this technology is still very much the backbone of robotic automation even when it takes the form of a cobot,” says Wade.

Industrial robots in the spotlight

He believes that there is currently so much emphasis on adopting the latest technologies such as cobots that important technologies like industrial robots are being overlooked.

“2023 marks 50 years since KUKA introduced the world’s first six-axis fully electric robot and the technology has consistently evolved since then to provide the robustness needed for demanding production environments like the automotive industry,” Wade explains.

In comparison to cobots, industrial robots offer a wide range of benefits including higher speeds, higher payloads, lower cost and models built for custom environments.

Historically, when industrial robots have been built into a system, they were constrained to a limited range of tasks due to the fixtures and hardware mounted around them. However, today, enabling technologies like high-quality and affordable vision systems, improved simulation and CAD/CAM software, combined with improved computing power has allowed users to realise the full flexible potential of industrial robots and help retain some of their freedom.

“Cobots also offer manufacturers some advantages due to the ease of programming, which may be important for contract manufacturers for example, and the ability to collaborate with people on tasks that marry human and robotic capabilities into one solution.

But often, cobots are being deployed in applications where ease of programming is not important, and there is no need for a person to be working in the same space as the robot, or where a risk assessment determines an external safety system is still required – so in these cases the advantages are negated, and an industrial robot may have been a better option,” says Wade.

Exceptions to the Industry 3.0 rule

However, Wade notes that both cobots and robots could be seen as fitting the aforementioned definition of Industry 4.0 when integrated with external systems or using a high level of data visualisation and decision-making.

“An example of this would be an IoT solution where data monitoring of the robot’s performance is captured by a factory-wide dashboard which also provides insights into the robot and the plant’s performance. This allows managers to optimise energy use and predict maintenance requirements. Looking to our own cohort, the Open IIoT demo unit showcases this capability with KUKA’s LBR iiwa Cobot connected to a ZI-Argus Symbiont platform.”

A final scenario where robots and cobots are classified as Industry 4.0 technology, is in instances where mass customisation, or small batch production is needed, and the robot or cobot provides for high-quality production of very small batches thanks to their ease of programming.

Insight into the future of robotics

Wade is optimistic about the future of robotics in Australia, citing advancements in the development of mobile robots as one interesting area for growth.

“By mobile robots I’m not just referring to a mobile platform like an AGV or AMR but a six-axis robot integrated with an autonomous mobile platform. This technology will really transform what we consider possible and will lead to companies designing factories in new ways so that large workpieces can be transported to the required processing station, on demand.”

He adds that automated production no longer means ‘production line’ and that advancements in robotics will accelerate the shift towards efficient batch size one.

“When thinking about cobots, think about what functions are needed, and don’t jump straight to the specific technology - you may be surprised to find a more traditional robot will perfectly fit your needs. Make sure you talk to a robotics provider that can provide a complete range of different types of technology, to explore what’s right for your specific circumstances,” Wade concludes.

Website: https://openiiot.com.au